«We have been collaborating with the company THEODOROU AUTOMATION almost since the beginning of our own company, and we use their products and services for coding our products. This helps us with our own traceability as well as with the logistics of our demanding customers.».

Athanassios Kerasiotis

Production Manager, GAEA FOODS SA

About GAEA FOODS SA

GAEA FOODS SA was founded in 1995 with the vision to introduce the world to high quality, authentic, healthy and delicious Greek Mediterranean foodstuffs that were absent from the market. GAEA sells in most major markets across the world and exports account for 82% of the company’s annual turnover. GAEA’s factory consists of 3 fully automated production lines for olive oil, olives, dips, sauces and other biological products.

The Need

According to Mr Kerasiotis Athanasios, Production Manager of GAEA FOODS SA, «the proper coding of packages helps us offer what the customer/ distributor requires at any country that we export: automatic traceability and logistics. Our procedures are now based on the barcodes of the products. There are cases where the warehouses of our distributors, mainly in Germany, the Scandinavian countries and America, are fully automated».

The Solution

The solution that we offered includes both primary and secondary coding for olive oil products. Labeling is really important, at all packaging levels, in order to ensure traceability as well as smooth data flow during logistics processes.

Our coding solution allows:

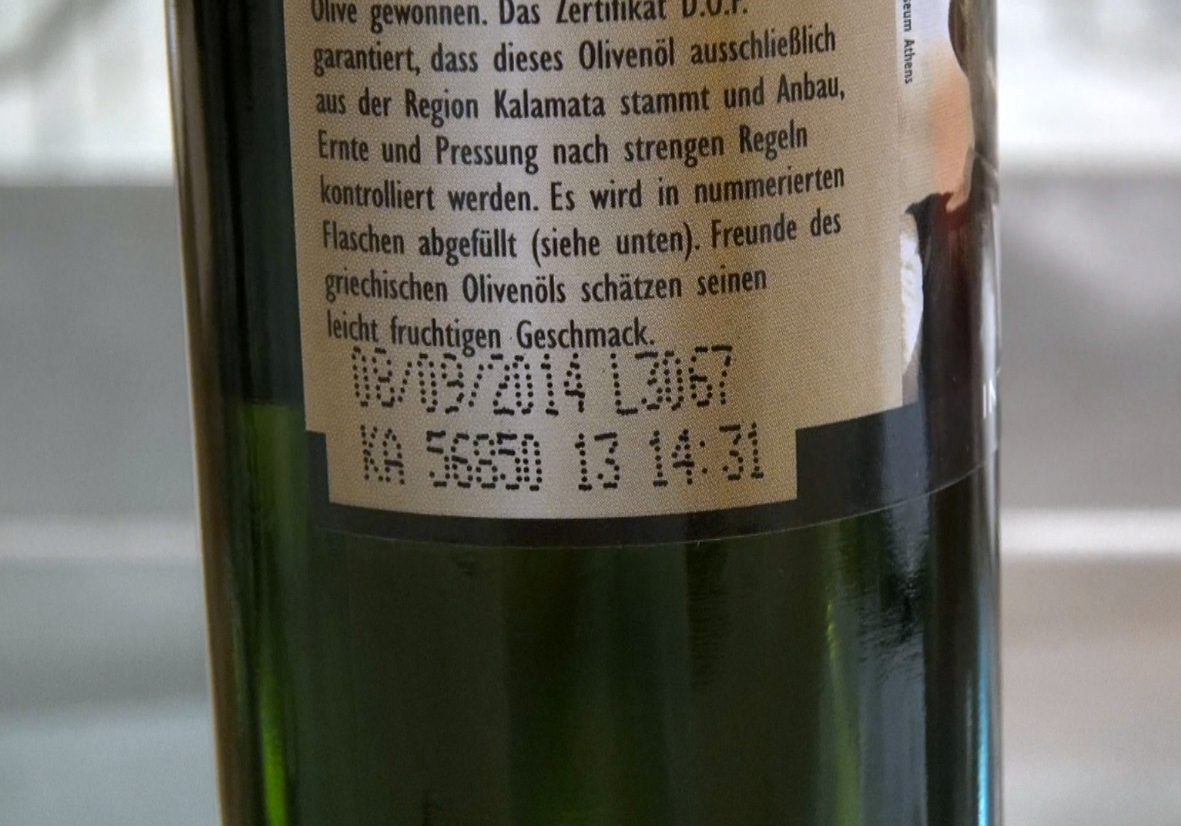

- Automatic label printing of variable data (Lot, expiry dates, barcodes) for bottles of olive oils.

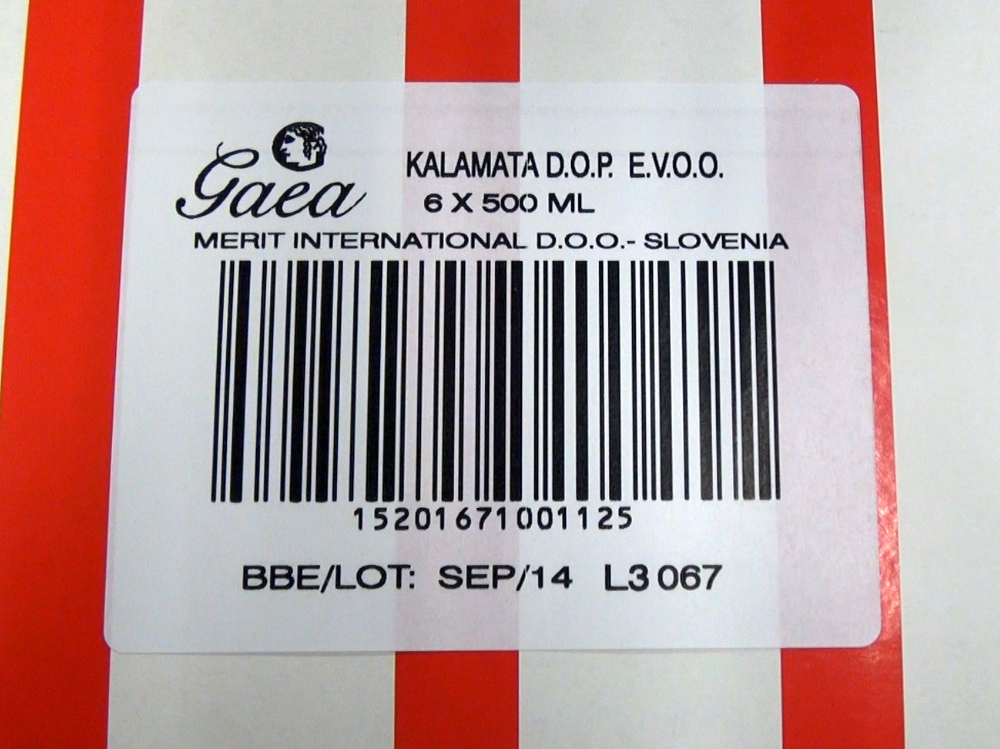

- Automatic labeling (Print & Apply systems) of logistics data (barcodes, company details, costumer details, lot, logo) onto carton cases.

Coding of Oil Bottle

Carton Labeling

For printing on the product, a modern continuous flow inkjet industrial printer (Domino Inkjet) was used, while for printing on the cardboard box, an automatic Print & Apply system was utilized.

The Benefits

The benefits that arose from the automatic printing solutions for GAEA FOODS were the following:

- Traceability

- Production increase

- Reduced inks use

- Error minimization

- Cost reduction

If you are interested in a similar solution, please call us on tel. +30 210 6690900 or fill out the contact form below:

Food / Beverages