The Client

TSATSOS GEORIOS “COSMETIC” company, which is active in the production of private labeled cosmetics and in the development of new products from the idea stage to the final product and its mass production, was looking for a comprehensive and flexible automation solution at the primary packaging stage, in terms of labeling products and their dynamic coding, in order to meet the growing demands of its customers. In particular, due to the production activity of private label products, the company sought to strengthen its competitiveness in such a way that it is able to undertake and carry out flexibly and at the lowest possible cost, high-demand partnerships with many different packaging formats which cannot be predetermined.

THEODOROU AUTOMATION SAICT, member of THEODOROU GROUP, responding to this need designed and implemented a complete and innovative labeling system that ensures increased productivity, reduced costs and fully meets the customer’s needs for flexibility in coding and packaging.

The Need

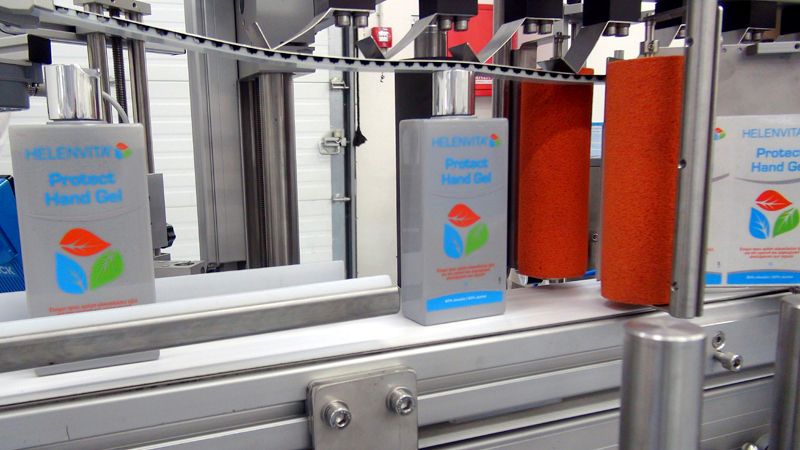

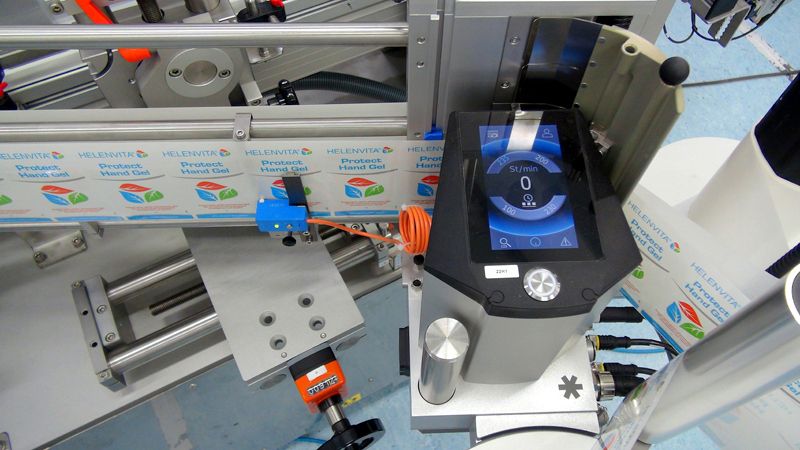

In the company’s factory there was on the one hand the need for automatic lateral labeling on up to two antisymmetric sides of oval and parallel containers and on the other hand for perimeter labeling in cylindrical and conical bottles at a rate of up to 45 pieces / min with one machine which is able to handle different containers and in a wide range of sizes (from a few ml up to 2lt), as well as to have a printer for online printing of dynamic information (lot number, expiration date) on the label during the apply stage. An additional requirement of the customer, which arose from a new collaboration after the initial assignment of the project to THEODOROU AUTOMATION SAICT and before its delivery, was the oriented labeling in a cylindrical container with precision and within specific frames with embossed border.

The Solution

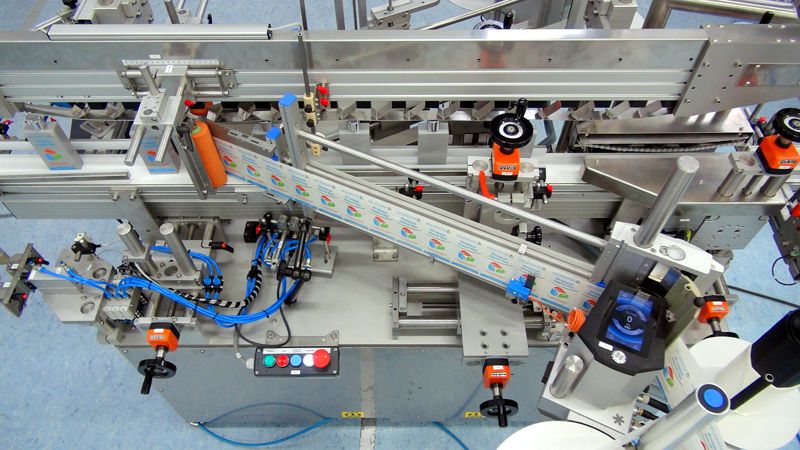

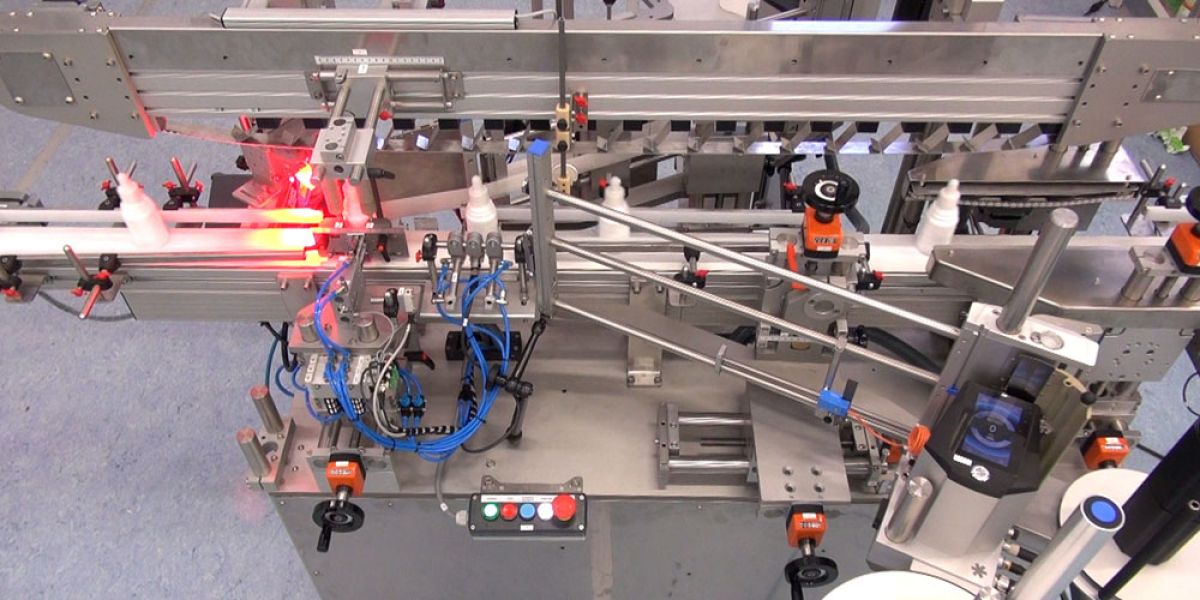

THEODOROU AUTOMATIONS SAICT after a technical analysis of the existing need and guided by the reliability of the system in the existing requirements and by the required flexibility in future, offered a complete and innovative high-tech solution to the customer. More specifically, the approach chosen for automatic labeling was an automatic double-sided and perimeter labeling machine consisting of two Herma H500 VS labeling heads suitable for labeling up to 240mm in height, with a special Markem SDX40i thermal printer and special separation, alignment, product retention and label coating modules, during the gluing stage, which ensures excellent gluing accuracy and repeatability. In addition to the machine, following a new need of the customer which concerned oriented labeling and emerged after the initial assignment of the project, a special position detection camera and appropriate automation was added for the automatic angle recognition of containers and labeling within specific frames.

Solution differentiation

- Great flexibility in packaging formats and dimensions

- Modular layout easily upgradeable with additional heads (eg top and / or bottom attachment) or modules (eg safety tag)

- 21 different containers (parallelepiped, oval, cylindrical, conical, jars, vials, with different lids) all manageable by one machine

- Immediate configuration and changes of applicators from product to product in times <1min

The Benefits

- Reliable operation combined with minimal need for operator monitoring

- Great ease of operation

- Truly automatic start – stop

- Minimum operating costs (maintenance and consumables)

- High availability

- Absolute flexibility and excellent gluing quality

- Made of stainless steel and aluminum, suitable for any industrial space (with humidity, dust, extreme ambient temperatures, etc)

- Possibility of future upgrade of the device to meet new needs

Click on the photographs for a larger view:

If you are interested in a similar solution, please call us on tel. +30 210 6690900 or fill out the contact form below.

Pharmaceuticals / Cosmetics