The Customer

The customer is a Greek company in the food production industry, specializing in deli meat products, with a particular focus on sausages. A benchmark in the production of traditional and healthy deli meats for three generations, the company combines top-tier mechanical and technological equipment with extensive controls at all stages of production to ensure the delivery of safe, high-quality products.

The Need

During the production process, the products exit the molds in multiple shapes and sizes, and in various layouts (parallel, grouped, or individual). The customer needed to automate and optimize two critical stages before the label application phase:

- Sorting of the products in sequence, coming from multiple production lines.

- Orientation of specific products, such as those with an easy peel feature, where the easy peel side must always be correctly positioned for label application by the labeling machine.

The Solution

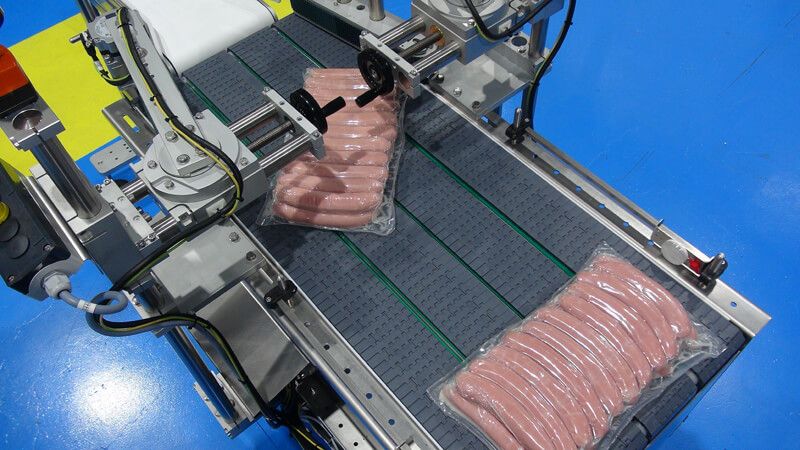

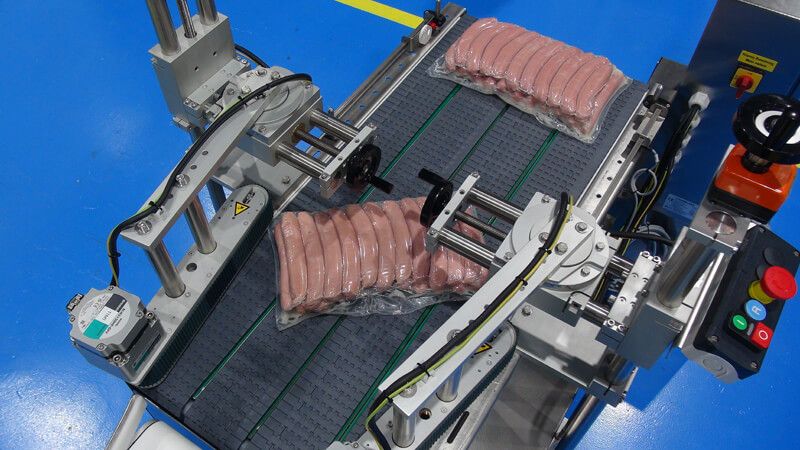

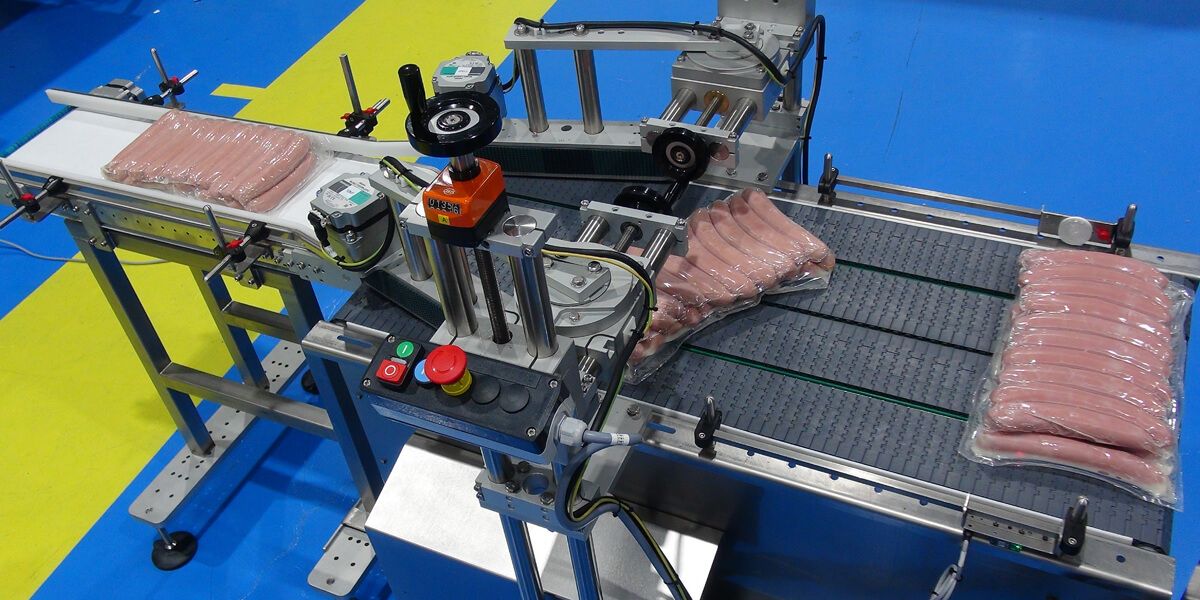

The Theodorou Group designed and installed a compact and flexible channelizer-type machine, specially adapted to the customer's requirements, offering automatic sorting and orientation of incoming products. The machine features 4 lanes, with programmable configurations for different product setups, allowing flexibility in handling individual or grouped units:

- 1x1: 1 product from 1 line (automatic orientation)

- 2x2: 2 products from 2 lines (automatic sorting)

- 4x1: 4 products from 1 line (automatic sorting)

- 2x1: 2 products from 1 line (automatic orientation & sorting)

To address the orientation requirements, two systems were implemented:

- Automatic rotation via the channelizer (for larger and heavier products)

- Mechanical rotation via an obstacle at the end of the line (mainly for lighter products)

Finally, the channelizer's output includes a faster conveyor belt to separate the products and feed them into the labeling machine with the correct spacing.

The Benefits

The delivered solution provided the customer with:

- Automatic product sorting, regardless of shape or layout

- Automatic rotation based on the easy peel, ensuring consistent label placement

- Automatic product spacing at the output

- Flexibility in handling different mold types and product dimensions

- Reduced manual intervention and improved performance of the labeling machine

- Space-saving, due to the compact design of the machine

Click on the photographs for a larger view:

If you're interested in a similar solution, call us at +30 210 6690900 or fill out the contact form below.

Food / Beverages

Automatic Handling & Sorting