Case Studies

Read our case studies

- Home

- Case Studies

Robotic Case Packing System at the Cypriot Food Company SERANO

The cypriot food company SERANO was seeking an automated solution for the secondary packaging processes of two of its production lines. ZENON AUTOMATION SAICT, a member if the THEODOROU GROUP, designed a robotic system for packaging products of various sizes, requiring minimal adjustments during changeovers. The system either boxes packages of nuts into cardboard boxes or groups them for heat shrink wrapping.

Coding of Primary and Secondary Packaging at KONVA SA

KONVA SA canning company needed a coding solution for both primary and secondary packaging. The THEODOROU GROUP installed an inkjet industrial printer for primary packaging, providing seamless online management of information. Additionally, a print-on-demand industrial printer was installed for secondary packaging, effectively replacing adhesive labels with direct printing on the boxes for improved efficiency.

Automatic Parcel Sorting & Weighing System at SKROUTZ LAST MILE

ZENON AUTOMATION SAICT, a member of the THEODOROU GROUP, designed and installed an automatic sorting system at SKROUTZ LAST MILE courier company in its sorting and transportation center (HUB) in Athens, Attica, Greece. This system consists of an automatic sorting machine and a volumetric measurement unit, thereby accelerating the sorting process of parcels and reducing potential errors.

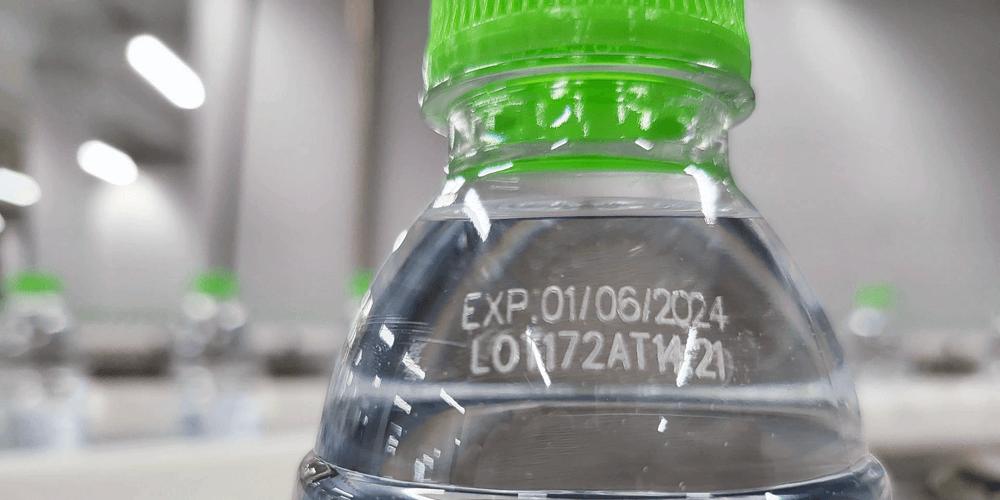

Coding of Bottled Water with Industrial Laser & Inkjet Printers at DIRFYS SA

THEODOROU GROUP successfully installed two industrial laser printers at the DIRFYS SA factory, for coding of the primary packaging, as well as an industrial inkjet printer for coding of the secondary packaging. This implementation achieves high print quality, even at high production speeds, and an aesthetically pleasing result in the labeling of its products, aligning with the company's commitment to quality and visual appeal.

Full Automation of Parcel Sorting and Sorting Processes at SPEEDEX SA

ZENON AUTOMATION SAICT designed and installed an automatic sorting system at the sorting and transportation center of SPEEDEX SA in Attica, Greece. The system consists of a small parcel sorter for packages weighing up to 5kg and a large parcel sorter for packages weighing up to 15kg, successfully speeding up the sorting process for parcels and envelopes, while also reducing any potential errors.

Full Automation of Seven Packaging Lines At SYNGENTA HELLAS SA

THEODOROU GROUP, responding to SYNGENTA HELLAS SA company's needs, implemented the complete automation of all packaging processes for the seven production lines at SYNGENTA's factory in Greece, providing all the required mechanical equipment and participating as an integrator in the implementation of the full traceability project, which extends down to the item level (serialization & aggregation).

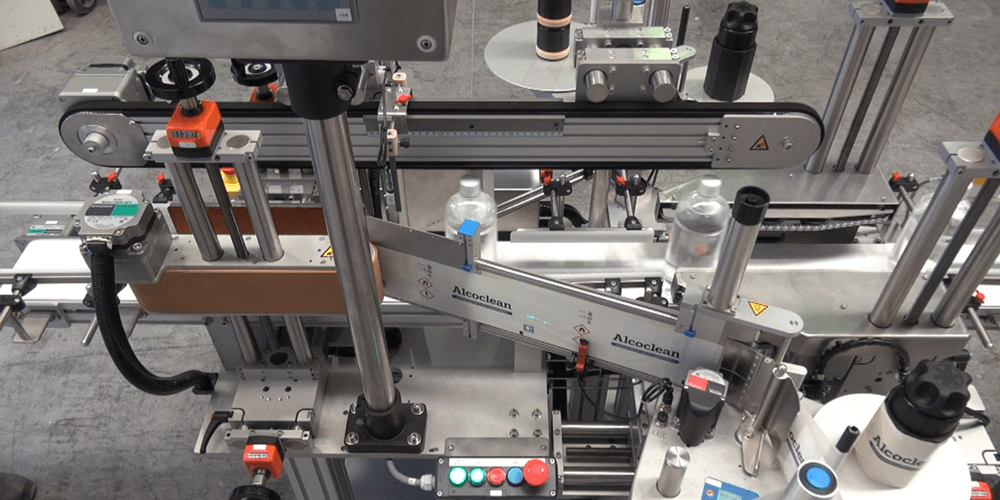

Complete Labeling System for Demanding Applications at MULTICHEMICAL SA

MULTICHEMICAL SA was looking for a solution for automatic labeling of the packaging of the products it produces. THEODOROU AUTOMATION SAICT, member of the THEODOROU GROUP, designed and implemented an integrated automatic labeling system that fully meets the company's needs for labeling various product packages (shape, size, material, etc.) produced by the company, achieving high quality and speed.

Automatic Order Execution System At A. PAPANIKOLOPOULOS SA

ZENON AUTOMATION SAICT implemented an automated order execution solution for the pharmaceutical warehouse APOSTOLOS PAPANIKOLOPOULOS SA, which integrated the company's old system into a new, modern system. The system includes: automatic collection of orders into boxes, automatic handling of boxes within the company, automatic invoicing, packing and sorting of orders by route, ready for distribution.

Digital Transformation Solution of Production Processes at CAVINO SA

THEODOROU GROUP, with extensive expertise in robotics, automation and digital transformation solutions for Industry 4.0, designed and implemented a comprehensive fully automated system for the production processes of KAVINO SA wine production company. This system includes robotics, End-Of-Line Automation, MES Tracer Factory and full integration of IT systems and production equipment.

Automatic Case Packing System of Feta Containers at DODONI SA

ZENON AUTOMATION SAICT, a member of the THEODOROU GROUP, with extensive expertise in designing and implementing robotics and automation solutions for end-of-line processes, successfully delivered a turnkey automatic packaging system for plastic containers of feta cheese to DODONI S.A. The system offers complete automation, high productivity, enhanced safety and optimal space utilization for efficient operations.

Case Packing & Palletizing System 4 in 1 with Cobot at APIVITA SA

The cosmetics company APIVITA SA was seeking a solution for automating the case packing and palletizing processes of its products. THEODOROU AUTOMATION SAICT, a member of the THEODOROU GROUP designed and installed an innovative and compact system with a cobot that performs four tasks at the same time: forming cardboard boxes, grouping and case packing products, closing cardboard boxes and palletizing.

Labelling System at INTERCOMM FOODS AE

The food company INTERCOMM FOODS was seeking for an automation solution at the primary packaging stage, in terms of labeling its products, in order to meet the growing demands of its customers. THEODOROU AUTOMATION SAICT designed and implemented a comprehensive and innovative labeling system that increases productivity, reduces costs and offers flexibility in labeling primary packaging (jars of various shapes).