Case Studies

Read our case studies

- Home

- Case Studies

Case Packing & Palletizing System 4 in 1 with Cobot at APIVITA SA

The cosmetics company APIVITA SA was seeking a solution for automating the case packing and palletizing processes of its products. THEODOROU AUTOMATION SAICT, a member of the THEODOROU GROUP designed and installed an innovative and compact system with a cobot that performs four tasks at the same time: forming cardboard boxes, grouping and case packing products, closing cardboard boxes and palletizing.

Labelling System at INTERCOMM FOODS AE

The food company INTERCOMM FOODS was seeking for an automation solution at the primary packaging stage, in terms of labeling its products, in order to meet the growing demands of its customers. THEODOROU AUTOMATION SAICT designed and implemented a comprehensive and innovative labeling system that increases productivity, reduces costs and offers flexibility in labeling primary packaging (jars of various shapes).

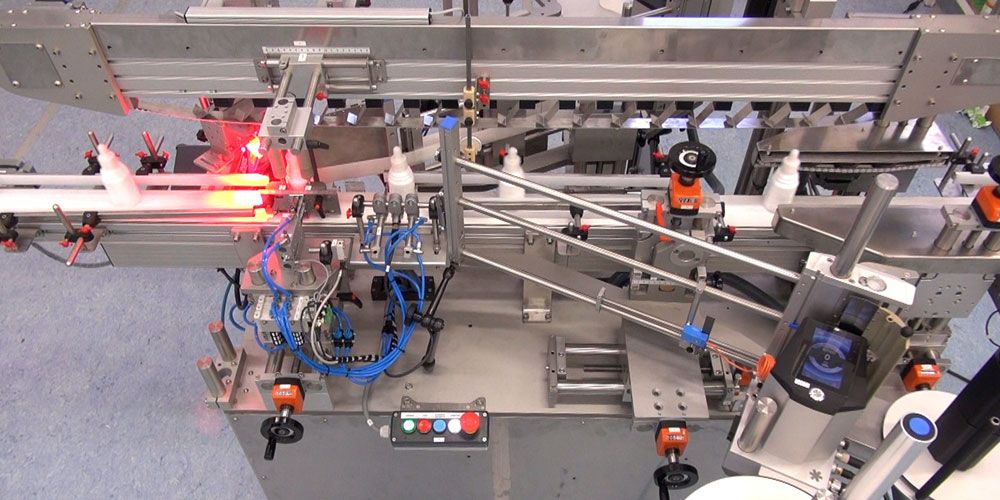

Labelling System at TSATSOS GEORGIOS "COSMETIC"

The cosmetics company TSATSOS GEORGIOS "COSMETIC" was seeking a solution for coding and automatic label application on its products to meet customer demands. THEODOROU AUTOMATION SAICT, responding to this need, designed and implemented a complete and innovative labeling system, that ensures increased productivity, reduced costs and fully meets the customer’s needs for flexibility in coding and packaging.

Drug Packaging Control System at GALENICA SA

GALENICA SA, as part of its production process and quality control, needed to verify the correct insertion of the medication's instruction leaflet into its packaging. THEODOROU AUTOMATION SAICT, a member of the THEODOROU GROUP, designed and implemented a system that checks the correct insertion of the leaflet and simultaneously features an automatic stop for the cartoner in case of an error.

Serialization Project at GALENICA SA

GALENICA, one of the largest greek pharmaceutical companies with innovative proprietary medicines that it has already successfully exported to the Balkans, in order to comply with counterfeit drug legislation, it needed a serialization system to use for its medicines production. ZENON AUTOMATION SAICT, in response to this need of GALENICA, designed and implemented a complete serialization in a box system.

End-of-Line System at EUROCHARTIKI SA

ZENON AUTOMATION SAICT, a member of the THEODOROU GROUP, automated the packaging and palletizing processes for five distinct production lines of liquid detergents at EUROCHARTIKI SA by designing and installing a comprehensive End-of-Line system at it spremises. Additionally, it transferred the palletizing process from the production area, where it was done manually, to the warehouse.

Case Handling & Palletizing System at NESTLE HELLAS SA

ZENON AUTOMATION SAICT, member of the THEODOROU GROUP, successfully completed the installation of a fully automated handling and palletizing system for three carton packaging lines. NESTLE HELLAS SA is the largest food company in the world operating in more than 80 countries. It offers a wide range of products including brands such as Nescafe, Loumidis, Nesquik, Korpi, Μaggi, Crunch, Friskies, Perrier, etc.

Automated Order Picking System at LION PHARMA SA

ZENON AUTOMATION SAICT, a company with extensive expertise in the design and implementation of robotic and automation solutions for the end-of-line, successfully completed a fully automated order picking and dispatch system for LION PHARMA, a company which specializes in the distribution of pharmaceutical products. ZENON collaborated with CSA, which supplied the ERP & WMS software of the line.

Robotic Repackaging Line at ATHENIAN BREWERY SA

ZENON AUTOMATION SAICT, a member of the THEODOROU GROUP, with extensive expertise in the design and implementation of robotic and automation solutions for end-of-line processes, delivered a turnkey re-packaging line for multi-pack beer at ATHENIAN BREWERY SA, the leading company in the beer industry with brands such as Amstel, Amstel Pils, Amstel Bock, Amstel Radler, Heineken, ALFA, Fischer, and more.

Robotic Palletizing System at FRIESLANDCAMPINA HELLAS SA

ZENON AUTOMATION SAICT, a member of the THEODOROU GROUP, successfully completed the installation of a robotic palletizing system for Tetrapak boxes at FRIESLANDCAMPINA HELLAS SA. ZENON's integrated solution includes two industrial robots, management of four production lines, automatic system for palletizing of Tetrapak boxes and automatic system for wrapping pallets with stretch film.

Robotic Palletizing System of Cans at KYKNOS SA

ZENON AUTOMATION SAICT, a member of the THEODOROU GROUP, automated the palletizing process at the food industry KYKNOS SA with a solution that includes robots for palletizing shrink-wrapped packages of metal containers and an automatic pallet wrapping system with stretch film. The system can handle four different sizes of metal containers and achieves a performance of up to 30 boxes per minute.

End-of-Line System at SYNGENTA SA

ZENON AUTOMATION SAICT, a member of the Theodorou Group, delivered a integrated system to SYNGENTA SA that automated the secondary and tertiary packaging process. The system, designed and installed by ZENON, includes two pick and place systems for bottle caps, three cartesian bottle boxing systems, a robotic palletizing of boxes system, automated stretch film wrapping system and lines & tanks SCADA system.