From Connected to Resilient Factory

Dr. Evangelos Theodorou presents the transition from the “Connected” to the “Resilient” Factory, drawing on real-world implementation experience of the Tracer Factory in an industrial environment. When data, systems, and people operate in a unified rhythm, the factory stops being a collection of departments and becomes a living organism. That is where true resilience begins: through interoperability.

Traceability and Serialization & Aggregation Systems in the Meat Industry

Dr. Evangelos Theodorou speaks to MeatPlace magazine about traceability and the systems of serialization and aggregation in the meat sector. In this interview, the modern solutions of Theodorou Group are presented, spearheaded by the Tracer Factory platform, offering complete monitoring, quality control, and transparency at every stage of the production process.

Technology as the Connecting Tissue of Industry

In this article, Dr. Evangelos Theodorou, President & CEO of Theodorou Group, examines the importance of technology as the connective tissue in modern industry. Real progress does not come merely from adopting new technologies, but from properly integrating them into a harmonious and flexible system that coordinates and improves all phases of production and distribution.

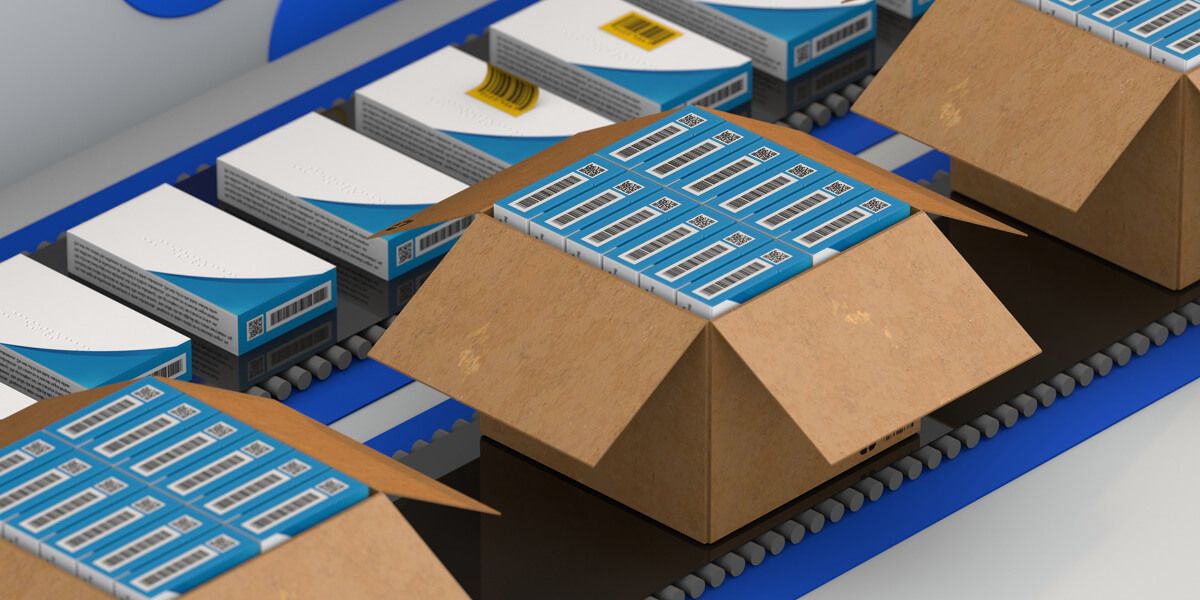

Applications of Machine Vision Technologies in Modern Industries and Warehouses

In general, the industry, as well as the production stages from product packaging to transportation to the final product warehouse, are experiencing a transformation due to the advancements in Machine Vision technologies (Cameras - Volumetric - Fixed Position Scanners). The applications of these technologies are crucial tools for modern production processes, offering advantages in efficiency and traceability.

Compliance with the Chestny ZNAK System for Exports to the Russian Market

The Chestny ZNAK system is a product track & trace system implemented by the Russian government to guarantee the authenticity, traceability, and quality of products. The Theodorou Group offers tailored solutions to companies wishing to export to the Russian market, ensuring their full compliance with the stringent requirements of the Chestny ZNAK system for smooth market entry.

Developments in Product Traceability and the Serialization and Aggregation Systems

In this article, Dr. Evangelos Theodorou, President & CEO of the Theodorou Group, informs us about the developments in product traceability and the Serialization and Aggregation systems—relatively new technologies that are now beginning to find application in the industry. These technologies can significantly contribute to the proper functioning and transparency of the supply chain.

The Present and the Future of Industrial Robotics

Industrial robotics has already transformed production processes, but its future promises even more advancements. From integrating artificial intelligence and evolving systems to the growing use of robots in supply chains, the potential for innovation is immense. Dr. Evangelos Theodorou explores how robotics will continue to shape the future of manufacturing and logistics, offering new opportunities for efficiency and productivity.

2D Codes in Products and the Challenges for the Industry

Barcodes are still scanned over 6 billion times daily, but as the demand for more information grows, many industries are beginning to adopt 2D codes for product packaging. The transition from 1D barcodes to the GS1 Digital Link, a 2D coding system intended to replace barcodes by 2027, aims to enhance information, improve supply chain transparency and provide detailed product information.

The Trends and Technologies that are Changing the Face of The Supply Chain

Over the past two decades, significant steps have been taken to modernize the supply chain resulting in significant cost reduction and increased productivity. It is expected that these modernization trends will intensify over the next five years and that the supply chain will evolve into an significant source of added value for businesses. The catalyst is the technologies that can be adapted to all business sizes.

New Technologies For the Safety of Consumer Products

Food and consumer product safety is the most decisive factor for consumers when making product choices. Businesses involved in production, storage, distribution, and sale must adhere to strict regulations to ensure that their products reach the final consumer in the proper condition, while consumers increasingly demand more information about the safety of these products.

Is Greek Industry Ready for Industry 4.0?

It is a fact that Industry 4.0 offers a unique development opportunity for industrial, and not only, businesses. It is a reality and it is here to bring the future. Our long-term engagement with industrial digital transformation shows us that most Greek industries seem to understand the basic principles and technologies of Industry 4.0. But there is quite a lag in understanding how to properly use them to meet their needs.

The Industry 4.0 Applications

It is a fact that there is a lot of information about the new industrial revolution and the technologies that support it. Knowledge of these technologies is essential for industry executives who are responsible for developing strategies for integrating digital transformation. The question, of course, is how technologies lead to applications that provide real solutions to the problems facing the industry.

- 1

- 2