Announcements

Be informed about announcements of the Theodorou Group companies

Voluntary Blood Donation at THEODOROU GROUP

At THEODOROU GROUP, we believe in the power of social contribution and the importance of voluntary blood donation. As part of our group’s scheduled Corporate Social Responsibility actions, we held a voluntary blood donation for the 2nd time this year at our facilities in Peania, Attica, Greece in collaboration with the National Blood Donation Center, a body under the Ministry of Health.

The Integration Progress of the Arcon Group into the Theodorou Group

It has been 18 months since the 100% acquisition of the ARCON GROUP OF COMPANIES by the THEODOROU GROUP. ARCON operates with wholly-owned subsidiaries in 9 countries: Czech Republic, Slovakia, Hungary, Bulgaria, Georgia, Armenia, Azerbaijan, Kazakhstan, and Uzbekistan, active in industrial coding, traceability, and product labeling.

Successful Organization of Theodorou Open Days 2025

The Open Days event, themed “The Development of Greek Industry and the Professions of the Future – The Role of New Technicians”, was successfully held on Thursday, April 10, and Friday, April 11, 2025. The event was organized by the Theodorou Group with the support of the Hellenic Federation of Enterprises (SEV) and the General Secretariat for Vocational Training of Public SAEK (formerly Public IEK).

Theodorou Group Collaboration with Labeling Greece SA

The THEODOROU GROUP and LABELING GREECE SA announce their strategic collaboration in color self-adhesive labels. LABELING GREECE SA has over 25 years of experience in label printing and operates a fully integrated self-adhesive label production plant (design / study, pre-press, production, quality control).

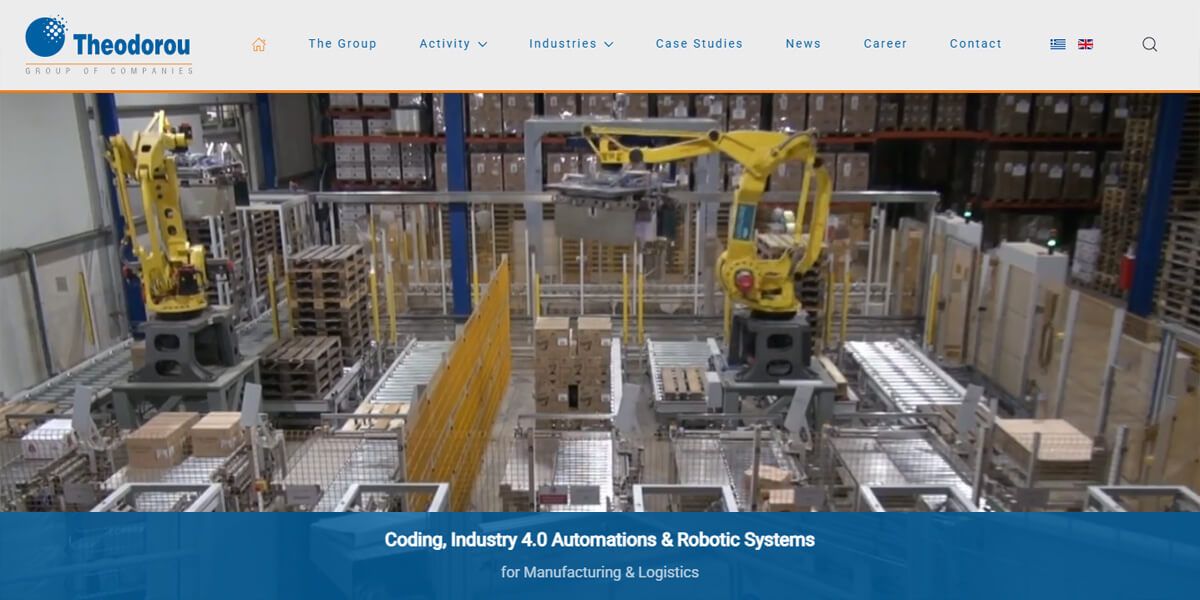

Refreshed Website for the Theodorou Group

The Theodorou Group presents its refreshed website, which offers a more modern, user-friendly, and responsive experience for its visitors. Designed for easy navigation on both PCs, laptops, and mobile devices, it ensures access from any type of device, while fully showcasing the Group's solutions, products, and services. Navigate our refreshed website and discover the solutions, products, and services we can offer to your business!

Strong Technical Support Team in Northern Greece

THEODOROU GROUP's technical support team in Northern Greece is distinguished for its expertise, providing high-quality services with immediacy and reliability. At the recent 2025 New Year’s cake cutting event in Thessaloniki, the management expressed its satisfaction with the team's performance, celebrated a successful year, and set goals for the upcoming one, continuing the groups' commitment to innovation and high-quality.

Voluntary Blood Donation at THEODOROU GROUP

At THEODOROU GROUP, we strongly believe in the power of social contribution and the significant importance of voluntary blood donation. As part of our planned Corporate Social Responsibility activities, we successfully organized a voluntary blood donation drive at our facilities in Peania, Athens, Greece, in collaboration with the National Blood Donation Center and the General Hospital of Athens - ELPIS.

Expansion of Theodorou Group’s Labeling Systems Manufacturing Plant

The Theodorou Group announces the expansion of its factory for the manufacturing of automatic labeling systems and devices in a new 2,000 sq. m. facility in Paiania, Attica Greece. With over 10 years of experience in producing labeling systems, the Theodorou Group has delivered more than 500 labeling devices to industries such as food, beverages, pharmaceuticals, cosmetics, and more.

Theodorou Open Days: Our Priority is Creating a New Generation of Technicians

The Open Days themed 'The Role of New Techniques in the Development of the Greek Industry,' organized by Theodorou Group, were successfully held and well attended. We informed the students—budding technicians—about the important role they will play in the ongoing development of Greek industrial enterprises, the responsibilities of various technical departments, and the essential skills that are required.

We are Looking for our New Generation of Technical Consultants

Theodorou Group operates in Greece and 11 other countries, offering innovative technological solutions for the industry and supply chain. Our team of technical consultants is staffed by selected engineers of various specialties (electrical, electronic, automation, mechanical, production, etc.). If you are interested in joining our team, feel free to contact us.

Cyprus: Companies are Keenly Interested in Industry 4.0 Solutions

The event organized by Theodorou Group in Cyprus was successfully held on March 12 2024 in Limassol. On the occasion of the integration of the Cypriot company Matrix Automation MK into the group, we invited company executives in order to be informed about the range of modern solutions we provide, the transition of the industry to digital transformation and to discuss together the needs of each sector.

Emphasis on After Sales Technical Support by Theodorou Group

The Theodorou Group, since its inception in the early '80s, has recognized the significant value of after-sales technical support for its customers. For this reason, it has invested and continues to invest in properly trained field technicians, who are equipped with all necessary spare parts and supported by state-of-the-art information systems, in order to be able to provide high-quality services to its customers.

- 1

- 2