SPEEDEX is one of the largest companies in the courier sector, meeting daily the needs of the Greek and international market with reliability and consistency. It was founded in 1986 offering guaranteed urgent transports and today it has been present in the Greek market for 30 years. It has an autonomous network of 200 stores nationwide and its development continues by constantly upgrading the quality of its services, implementing an electronic detection system (barcode), developing its computerized system, connecting its stores with a privately owned fleet of cars and exclusive flights.

Speedex SA wanted to speed up the process of sorting parcels and envelopes and at the same time reduce any related sorting errors at its facilities at its sorting and transport center (HUB) in Attiki, at the 14th km of the National Highway Athens – Lamia with a total area of 4000 sq. m.

Zenon Automations SAICT, a member of Theodorou Group, designed and installed an automatic sorting system which consists of 2 sorting machines (sorters): One for sorting small parcels up to 5 kg and one for sorting large parcels up to 15 kg.

The parcels are classified based on the barcode they carry on a label. As soon as the sorting system reads the barcode of the parcel, it looks up the Speedex database to which it is connected, gets the information of the destination and gives an order so that it goes to the corresponding output of the system defined for the specific sorting program. The time to do this is ~300-400ms, which is the time from the moment the barcode is read to the moment the parcel arrives at the entrance of the parcel sorting device.

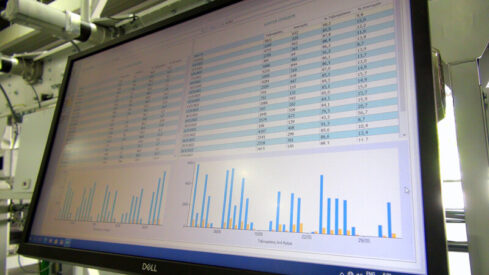

To sort the parcels, sorters are used, which consist of a special crawler with rollers, parts of which are activated, in order to divert the package appropriately to the exits located on either side of this crawler. Each of the sorters has 34 outputs, 17 and 17 in this case, their size can be larger or smaller according to the customer’s needs and each output can correspond to a destination or a group of destinations. Each sorter has its own sorting schedule, which changes depending on the time of day and the work performed by the sorting center. So, each output can be changed for another use, depending on the sorting program. At each of the exits there is an electronic display/tag, which writes the destination, so that it is easy for the operator to know the destination of the corresponding bag or cart and place them in the correct destination.

Also, the system automatically prints labels to mark the bags that small packages go into or the carts that large packages go into. Every time the sorting program changes, the information on the screens/tags, which communicate wirelessly with the system and are updated in real time, automatically changes as well. A packing list is created for each bag or cart, that is, all the packages that have been placed inside are recorded electronically, thus facilitating the traceability of the package and offering information on when this package passed through the sorting center, in which bag/cart it went and to which destination it was headed to or if it has already reached its destination. So, at the same time, the need to record the path of the parcel as it passes through the sorting center is covered.

The speeds that the sorters can reach are 5000 parcels per hour for the large one and 8000 for the small one. The sorter can handle any packages with a rectangular or nearly rectangular cross-section, while there is no particular problem if the package is wrapped in nylon or has reflections. In the large sorter, in addition to the barcode reader, a device has been integrated, which measures and records the dimensions of the package, its weight, as well as two photos, so that the condition of the package can be proven when it arrived at the sorting center . These are stored and searchable at any time. Based on the dimensions and weight of the package, the charges are made to the customer. In the small sorter there is no corresponding provision, because there the charge is fixed and is made per piece and has nothing to do with the volume of the piece.