KONVA SA is a modern fish processing industry, with an international presence, high expertise and many years of experience in the food processing industry. Its factory in Kilkis was built in 1989, is fully equipped, and certified according to the strictest quality standards. It has a production capacity of 200,000 cans per day and its workforce exceeds 200 employees.

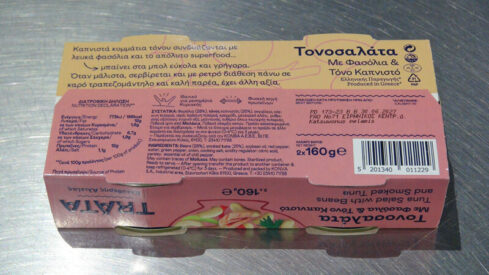

It produces a very wide range of products, frozen and canned, exports its products to 18 European countries, America, Canada and Australia, while in the Greek market it markets two dominant brands, TRATA and FLOKOS, intertwined with tradition and high quality .

Invests in state-of-the-art equipment, aims to develop new products and codes, always with environmental protection and innovation in mind, and bet on extroversion, which will make it one of the leading forces in Europe and in the food processing industry.

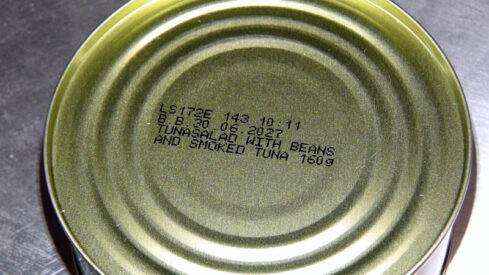

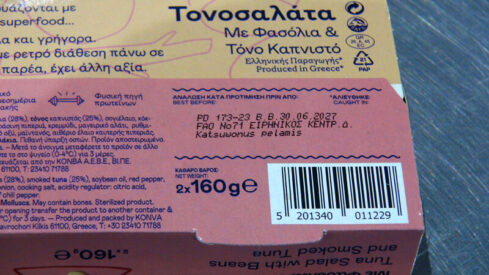

The KONVA SA factory has many codes, for many markets, and there was a need for a flexible and modern coding solution to print variable information on its products in the primary and secondary packaging strong>.

In order to cover the above need, KONVA SA decided to cooperate with THEODOROU GROUP, covering in the first phase the need for coding in the primary packaging (pieces) and in the second phase the need for coding in the secondary packaging (cardboard boxes). A very important factor for choosing THEODOROU GROUP as a partner was the immediacy and efficiency of the technical support it provides, as well as its expertise and know-how in the specific fields.

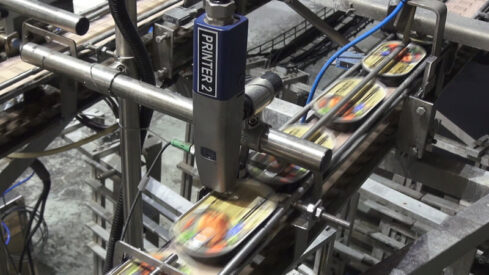

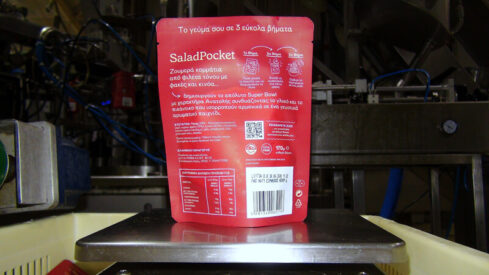

To meet the need for coding the primary packaging, one of the most modern models of industrial inkjet technology code printers of Domino, an internationally renowned company, represented by THEODOROU GROUP, was installed. The solution provides online management of variable information sent to print in production.

Regarding the secondary packaging, an industrial inkjet print on demand technology code printer, also from Domino, was installed. With this solution, the self-adhesive labels used to mark the cartons have been removed, and now the variable information is printed directly on them.